Aluminum-sulfur battery

The challenge has been to find chemical compounds that allow us to do this in a way that simultaneously meets the criteria of technical feasibility and economic feasibility.

In this attempt, an international team (Canada, China and the USA) decided to invert the traditional way in which research on new batteries: Instead of researching the most efficient compounds in energy storage and then trying to cut costs, Quanquan Pang and his colleagues took the cheapest elements and began to see the best they could do with they.

Aluminium-Sulphur Battery

The team started by studying the periodic table, looking for cheap and abundant metals on Earth that could replace the rare and expensive lithium. The commercially dominant metal, iron, does not have the proper electrochemical properties for an efficient battery, but the second most abundant metal on the market, aluminum, does have these properties – in fact, aluminum is the most abundant metal on Earth in terms of planetary composition.

The cheapest of all non-metals is sulfur, so it has become the preferred material for the second electrode.

It then remained to decide what to put as an electrolyte, the material to put between the two electrodes to transport ions back and forth during battery charging and discharging.

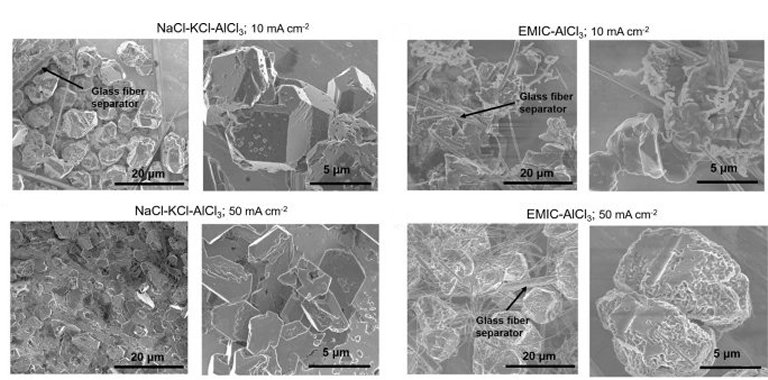

The team tested some polymers, but eventually turned their attention to a variety of molten salts, which have relatively low melting points — close to the boiling point of water, as opposed to over 500°C for many salts. A lower temperature makes everything cheaper because it eliminates the need for special thermal insulation and anti-corrosion measures.

In addition to building a cheap battery, the team found that their battery performs better technically than they themselves had expected.

Ultra-Fast Reload

This recharging speed was made possible by an unexpected advantage offered by the molten salt the team chose as an electrolyte. One of the biggest problems in battery reliability is the formation of dendrites, which are thin metal spikes that build up on one electrode, eventually growing until they come in contact with the other electrode, causing a short circuit. But this particular salt, thanks to its low melting point, is very good at preventing this malfunction.

Furthermore, the battery does not require any external heat source to maintain its operating temperature: Heat is naturally produced electrochemically by charging and discharging the battery.

This new battery formulation is ideal for installations of the size needed to power a single home or small to medium business, producing on the order of a few tens of kilowatt-hours. For larger installations, on the scale of tens to hundreds of megawatt-hours, the team is still betting on another technology, the liquid metal batteries that they created themselves a few years ago and that they hope to put on the market next year.

The smaller scale of aluminum-sulfur batteries could also make them practical for use as charging stations for electric vehicles. That’s why the team is also already trying to raise funds to make its commercialization viable.